Welcome to FPS Ltd

Subscribe

About Us

About FPS

Providing Energy Audits, Performance Surveys, commissioning and consultation within the Water and Wastewater industry.

Energy Audits to ISO 14414

FPS use the Systems approach to developing plans to reduce energy costs as well as improving reliability.

Benefits of Performance & Energy Audits

Accredited with CPSA (Certified Pumping System Auditor) conducting a site survey can help to reduce energy costs dramatically as well as increase reliability of assets.

Our Services

DO YOU HAVE A PROBLEM SITE ?

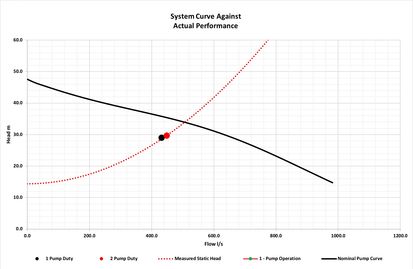

Understanding pump and system performance is key to saving energy and solving performance related issues which lead to high operating maintenance and energy costs.

Sending engineers to site without the correct skill set can also lead to excessive costs without a solution!

SITE VISITS & ANALYSING DATA

Understanding data is very important to optimise a pumping system.

The site visit gathers valuable data while our Analysis helps to understand existing asset performance before making our recommendations.

Analysis helps to develop answers which deliver energy and operational savings for the site.

DELIVERING RESULTS

Previous experience indicates energy savings can be up to 60% with 80% operational savings.

FPS offer best advice to reduce risk while Optimising Performance. Capital Payback for our clients are around 3 Years although can be significantly less depending on the application.

ENERGY AUDITS

ENERGY AUDITS ISO 14414

Energy Efficiency Directive (EED), ISO 14414 was developed and Chaired within ISO by the British Pump Manufacturers' Association (BPMA) working alongside other pump industry experts from around the world . The specification given to the working group was to deliver a high standard and independent route of Auditing Pumping Stations.

To understand achievable savings on pumping equipment, you first must understand the system demand and the operating conditions of the pumps. ISO 14414 offers information on how to carry out a pump system energy audit which in turn helps to evaluate if the pumping system is using the best pump for the application. This will also highlight any maintenance issues, where remedial work or replacement units may be required to increase pumping efficiency and reliability.

By understanding the Systems Engineering of how the pumps, pipework and control philosophy operate together, helps determine best course of action to optimize the station, limit failure rates and reduce energy consumption.

The BPMA developed a independent training scheme to help deliver ISO 14414 into the UK called Certified Pump System Auditor Scheme (CPSA).

Benefits of Performance & Energy Audits

Energy & Performance Audits

FPS was set up to offer Energy Audits, Performance Optimization and Consulting / Commissioning into the Water Industry. Founded by David White, FPS seen this as an opportunity to give impartial advice to clients ensuring decisions made on investment are based on factual information.

We have vast experience on pumping equipment within the water industry, gaining qualifications in Value Based Sixth Sigma Processes and accredited with Certified Pump System Auditor (CPSA) for ISO 14414. Our ability to merge the mechanical and systems engineering of pumping into the electrical, Instrumentation and control aspects of pumping stations is second to none, which is a proven system to deliver results for enhanced performance optimization and sustained energy efficiency.

Our audits can also include rising main pressure and flow surveys using temporary logging and measurement equipment.

Our commitment is to give Best Advice to Reduce Operational and Energy Costs

Minimizing Investment and Delivering Results - UK Wide.

Contact Us

Send Message

Questions & Estimates

Please reach out at your convenience so we can discuss your project.

Contact: David White